● Technologies summary

| Process | Cu Pillar bump | Solder Bump | WLCSP | WLBGA | Au Bump

| Fan-out WLP |

| Products |  |  |  |  |  |  |

Wafer Size

| 8” & 12” | 8” | 12” Panel |

Bump Pitch

(um) | 80~100 (Typ)

30(inner pad)

50(outer pad) | 100~250 (Typ)

40~60 (Micro)

~ 40 (Devep) | < 400 | ≥ 400 | 20um (Min) | > 400um |

Line & Space : 15/15 um

(Qualified internal: 10/10 um) | Line & Space :

25/25 um

(Dev. 15/15 um) |

Bump Material

& composition | Pure Cu

with Solder cap

(Lead free) | Lead free (Sn1.8±0.5Ag)

Eutectic (Sn/37Pb:12” only) | SACxxx,

LFxx | Au | SACxxx |

| Passivation | PI / PBO / Low temp passivation material | NA | Epoxy |

Seed

| Ti/Cu(STD), TiW/Cu | TiW/Au | TiW/Cu |

UBM(Plated)

| NA | Ni only or CuNi(WLCSP), Cu only(WLBGA) | NA | Ni only, non-UBM |

RDL

| Cu only, CuNiAu(RDL finish product) | Cu only |

Qualification

| Under Mass production | Qualified |

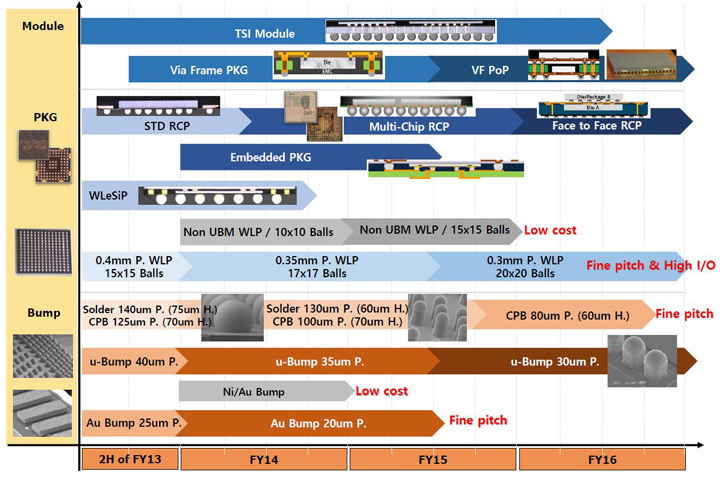

● Technology Roadmap

● Reliability Testing Capability

| Category | Equipment | Maker / Model |

Wafer Level /

PKG Level Reliability | TC Chamber | ESPEC /TSA-203ES-W |

| PCT Chamber | ESPEC / EHS-221M |

| HTST Chamber | ESPEC/ IPH-202 |

| Reflow | SEMI gear / GENEVA STP300 |

Test item

| Condition

| Sample Quantity

| Comment |

Precondition

(MSL1) | Bake | 125℃,24hours | 45ea | For Solder Bump |

Moisture Soak | 85℃/85% 168hours |

Reflow | 260℃,3回 |

HIGH TEMPERATURE STORAGE

(HTS) | -55℃? 125℃,各10min

500 Cycle | 45ea | |

TEMPERATURE CYCLE

(TC) | 121℃/100%RH

/2.0 atm168hours | 45ea | |

PRESSURE COOKER TEST

(PCT) | 150℃, 1000Hr | 45ea | |

● Analysis Capability

| Category | Equipment

| Utilization |

| Visual Inspection | Measuring Scope | PKG Dimension |

High & Low Power Microscope | 500x Magnification Visual Analysis |

Contact Profile | Bump height |

Sample

Preprocessing | Cross Sectioning Station | Destructive Package Cross Sectioning |

Decap solution | Internal Visual Inspection of Package |

Hot plate | Heating of sample or liquid |

| Chemical Analysis | ICP | Ag Chemical Analysis |

CVS | Cu Chemical Analysis |

Non-Destructive

Inspection | X-ray Scanner | Non-destructive Internal Characterization

Lead Configuration/Epoxy Void |

| Precise Analysis | SEM + EDX | 3-D analysis + Component analysis |

XRF (X-Ray Fluorescence spectrometer) | elemental analysis and chemical analysis |

| Physical Test | Dage4000 | Shear and Pull strength |

HV Tester | Bump Hardness analysis |